What Are The Advantages Of Pick And Place Robots?

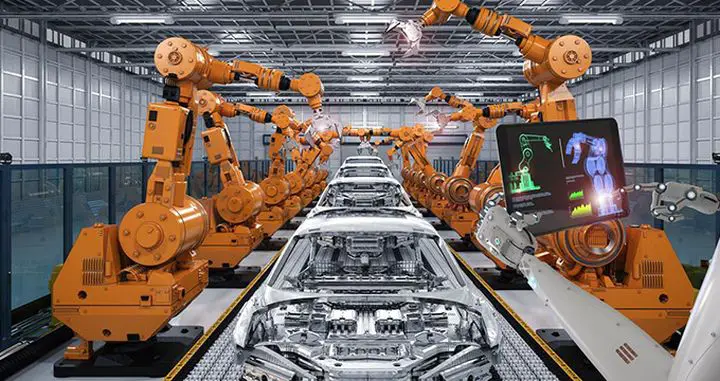

Automation is at the center of modern manufacturing. Whole industries have emerged because of robots. And some of these machines, such as pick and place robots, are highly beneficial for companies.

But what exactly do pick and place robots help companies with? What are the advantages of using them? We will look at all this in this article, so make sure to stick around.

1. Greater Flexibility

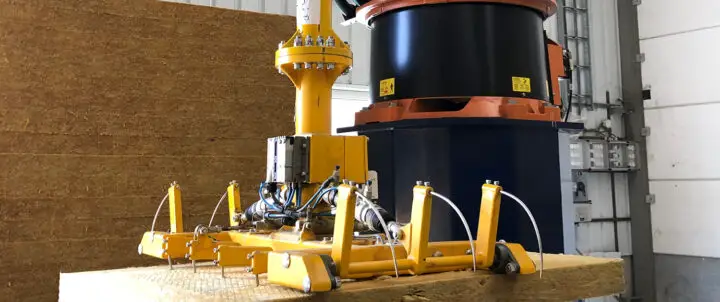

The first advantage of pick and place machines is flexibility. Companies can use these machines to perform a wide range of tasks. From assembly tasks to transporting large containers from point A to point B, they are easily programmable and can meet a company’s every demand.

Depending on the business and its needs, these machines can be specialized to perform specific business operations. Through the power of programming, an employee can operate these machines and streamline any process. Even if a new task emerges, these machines are flexible enough so that any operator can reprogram them to fit the businesses’ needs.

2. Easy To Use

Pick and place robots have gone a long way ever since their first introduction in the manufacturing industry. Nowadays, these robots have become very easy to use and operate.

It’s safe to say that not every pick and place robot is the same. There are fully automated robots, and there are semi-automatic and manual ones. The latter two require an operator to manually set preferences and the machine will do whatever the operator does.

But even if a company is using a manual pick and place machine, that doesn’t mean they’re not easy to use. The industry focuses a lot on perfecting these robots. As such, operators can be trained in using the robot.

Most of them come with instruction manuals that are very easy to follow through, where a company won’t require a specialist to come in and take charge of the operation. This advantage helps streamline operations and eliminates the need of hiring 3rd party operators to train your employees in how to use and give instructions.

3. Greater Efficiency

There is one undisputed advantage to using pick and place robots. While they are indeed flexible and easy to use, the most obvious advantage is that they are efficient.

Greater efficiency is one important reason why they are becoming so popular across many industries. The fully autonomous version of these machines can perform a wide range of tasks without employee supervision. More so, they have very high limits and can work 24/7. This makes them more efficient than employees and that is huge for businesses.

That way, businesses save money on needing to hire employees to take over these tasks. Even if they are more expensive to buy than to simply hire a couple of employees, the long-term efficiency benefits greatly outnumber the costs. As such, they are categorized as cost-effective solutions for any business.

They can be placed on the assembly line and take care of any assembly task needed. Furthermore, their use expands across dozens of industries.

4. Takes Little Space

Another advantage of using pick and place robots is that they take up very little space. Technology has developed a lot since the first variation of these machines. Ever since these machines have been improving in numerous ways. One of these is in the space department. P&P robots aren’t huge or vast. Their size is convenient enough so manufacturers can place them on the assembly line without taking too much space.

This is a huge benefit for manufacturers as it solves a very big issue. Factories can quickly become overcrowded, where employees lack the space needed to perform operations. With a machine that takes little to no space, manufacturers solve an important issue while also benefiting in more than one way.

5. Cost-Effective

We touched on this in a previous point, but these robots are so cost-effective that we have to explain it further. When we look at businesses expenses, there isn’t a bigger expense than hiring humans. Not only do humans require a salary, but they also require training. Training an employee can be quite costly.

More so, employees aren’t 24/7 available and can’t perform the same action as a P&P robot. They don’t perform it as effectively and as fast. So by replacing human workers with these machines, businesses can redirect their human workforce onto other departments and leave the menial work to machines that can operate 24/7 non-stop.

This saves a business a lot of money on having to hire workers to work three shifts. Since these machines never stop, all companies have to do is make sure they don’t break down. Even so, these machines are so advanced that they can perform under high amounts of pressure and for long durations of time without needing a break to cool off.

6. Little To No Maintenance

It’s no secret that these machines are state-of-the-art. They use the latest technology that makes the machine better in every sense of the word. From higher speeds to greater flexibility, they have it all.

But many would imagine one such machine to be a high-maintenance burden. That is simply not the case. Pick and place robots utilize the latest tech that makes them very easy to maintain. They don’t require nearly the amount of attention as previous generations and a company can train employees in-house to take care of maintenance needs.

Every now and then, one of these machines will require some maintenance. But thinking that it will be a daily chore is simply not true. What pick and place robots require in terms of maintenance is cleaning the machine, changing parts, oiling, etc. But this is the bare minimum companies need to do to make sure the machine works seamlessly for months.

Conclusion

Pick and place robots can fully streamline any business operation. As such, it would be wise to invest in them. If your business revolves around manufacturing, then you will experience all the benefits we’ve included in this article.